How To Build Concrete Forms

Assemble your concrete form. Building a straight form for concrete is fairly simple as long as the correct techniques are used.

How To Build A Straight Form For Concrete 6 Steps With Pictures

How To Build A Straight Form For Concrete 6 Steps With Pictures

Adhere the foam to the form with double-sided carpet tape and caulk around the edges.

How to build concrete forms. Mixing concrete in a wheelbarrow. This will make the edges smooth enough that there is no need to apply tape to them. Using insulated concrete forms is not easy.

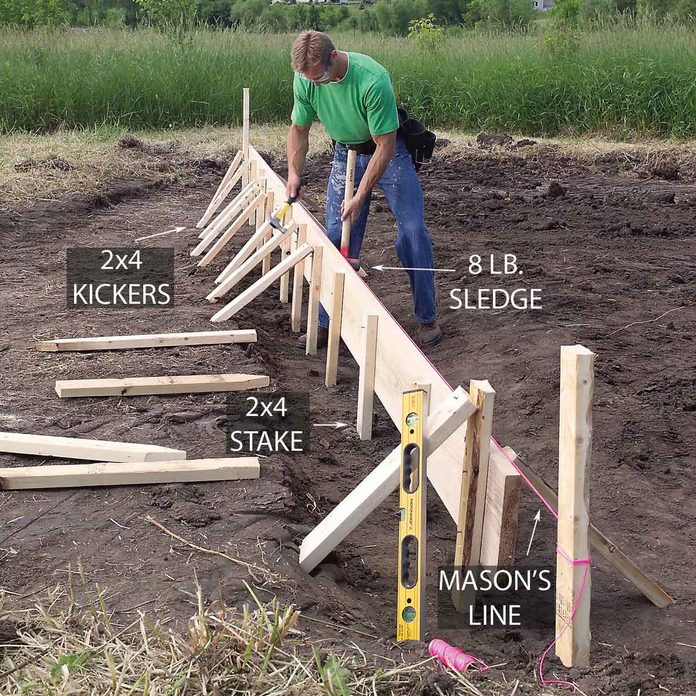

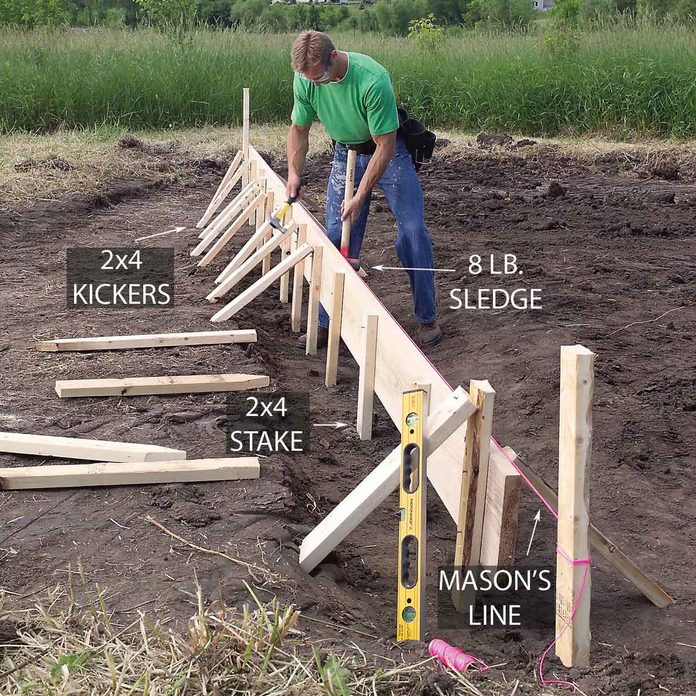

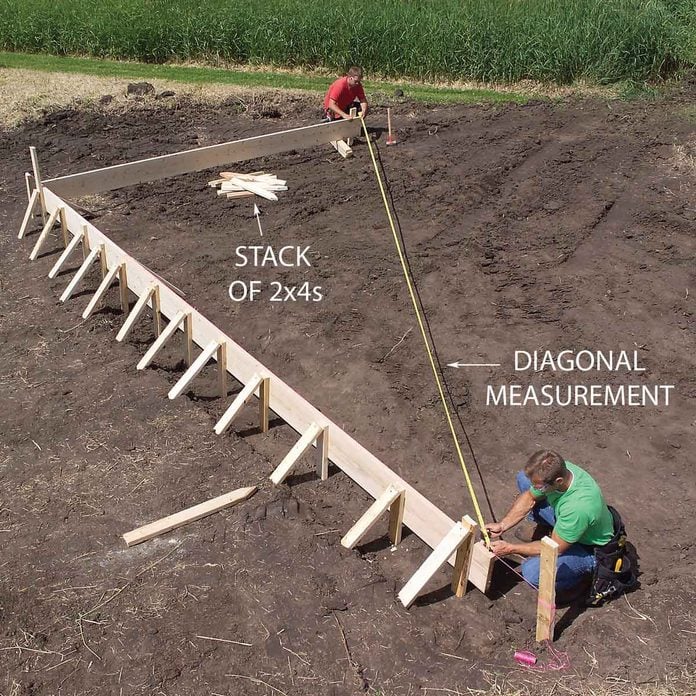

Cut a 2x12 to length or splice it with a cleat for one side of the concrete forms and nail it to a corner stake. This article will refer to a slab form wall forms have completely different requirements. How to build a form for concrete slabform for concrete build how toFormForConcrete Build HowToBuild Concrete HowTo F.

It takes professional knowledge to build with this material. If they will be reused then use treated lumber. Use a router to cut the foam using a Masonite template as a guide.

Get home building tips offers and expert advice in your inbox. The best form for a particular project is often a function of the pour size the amount of concrete the form needs to retain and the pressure or weight that will be pushing against the form. Smooth the edges using a disk sander.

Use screws and a power drill to attach each riser form board to your stringers. The form will be lightweight and strong. For a 5-in-thick slab with thickened edges which is perfect for most garages and sheds 2x12 boards work best.

Level the 2x12 and nail it to the second corner stake. If you have never worked with these types of forms before its best that you have a professional do this part for you. If you still decide to attempt this on your own here is how you can place your own insulated concrete forms.

You can do this by laying each stringer form so the even bottom side of each stringer is flat on the ground and the zigzag side of the stringer is oriented with its points facing up. The depth and width of the concrete placement determine the bracing and forming material required. For example the typical concrete forms used for flatwork such as a patio driveway sidewalk or road range in height from 3 to 12 inches.

The 2 x 4s should be No2 kiln dried pine simply because it is cheap easy to work with and holds nails very well. Sign up for eletters today and get the latest how-to from Fine Homebuilding plus special offers. A step by step video detailing the process to set concrete forms on our Crewgar construction site.

2 x 4s and 34 forming plywood works best. How to Build Concrete Forms. Start by choosing straight form boards.

Building concrete-countertop forms.

Concrete Forms Forming Concrete With Wood Forms Youtube

Concrete Forms Forming Concrete With Wood Forms Youtube

Tips For Building With Board Form Concrete Boothe Concrete

Forming A Small Concrete Slab Fine Homebuilding

Forming A Small Concrete Slab Fine Homebuilding

Fab Form Fabric Formwork For Concrete Footings Columns Pilasters And Icf Foundations In Oklahoma

How To Make A Concrete Fire Feature How Tos Diy

How To Make A Concrete Fire Feature How Tos Diy

Concrete Forms And Pouring A Concrete Slab Diy Family Handyman

Concrete Forms And Pouring A Concrete Slab Diy Family Handyman

Concrete Foundation Forms Google Search Concrete Footings Framing Construction Building Foundation

Concrete Foundation Forms Google Search Concrete Footings Framing Construction Building Foundation

How To Form Concrete Walls With Pictures Wikihow

How To Form Concrete Walls With Pictures Wikihow

Concrete Forms And Pouring A Concrete Slab Diy Family Handyman

Concrete Forms And Pouring A Concrete Slab Diy Family Handyman

Build A Concrete Walkway Series Building The Form Fine Homebuilding

Build A Concrete Walkway Series Building The Form Fine Homebuilding

How To Build Concrete Forms Youtube

How To Build Concrete Forms Youtube

Concrete Forms And Pouring A Concrete Slab Diy Family Handyman

Concrete Forms And Pouring A Concrete Slab Diy Family Handyman

Concrete Steps Footing 1000 Ideas About Concrete Building Blocks On Pinterest Concrete Concrete Footings Concrete Forms Concrete

Concrete Steps Footing 1000 Ideas About Concrete Building Blocks On Pinterest Concrete Concrete Footings Concrete Forms Concrete

Comments

Post a Comment