Drywall Butted Seams

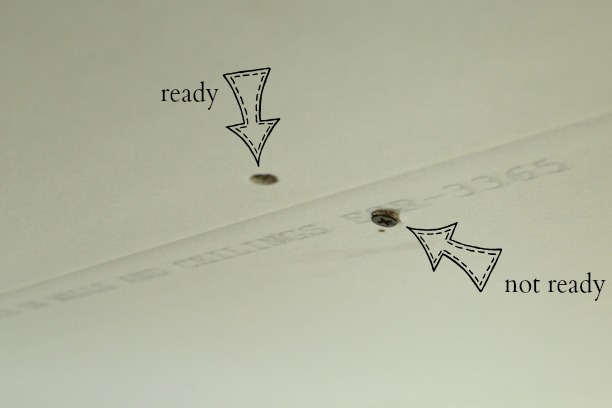

Here you can see the screw is set back from the edge to reduce damage to the drywall core. Also it is a good idea to avoid having drywall seams.

How Do You Like My Butt Joints Drywall Finishing Tips The Space Between

How Do You Like My Butt Joints Drywall Finishing Tips The Space Between

Butt joints occur on the ends of drywall sheets that arent tapered creating the potential for a bump along the seam.

Drywall butted seams. If playback doesnt begin shortly try restarting your device. In short the long edges of drywall sheets are tapered while the short edges are not. A tapered joint creates a subsection that is weaker than the rest of the drywall.

Butted seams are unavoidable when the wall or ceiling is longer than the available length of drywall. Staggering drywall joints throughout the wall ceiling doesnt provide any added structural support the important point to keep in mind is to line up all of the joints with a wall stud or ceiling joist. And because it falls between framing members its unlikely to crack or ridge.

How to fix Bulging Drywall Seams. We tape our joints in the usual manner beginning with the butt joints. How To Mud Coat a Drywall Butt Joint 4 seam and why you have to coat it WIDE - YouTube.

Butted two sheets of drywall too closely together. The seam on the right attached to a RockSplicer is a flat seam finished 12 inches wide. Why Drywall Should Be Staggered.

Its always best to avoid butted seams because unlike the sides of panels the ends are not tapered so hiding a butted seam is more difficult for the taper. Cut out the bulge and replace that section. As a DIYer you can justify overkill for personal gratification.

A butted seam is created when the ends of the panels are butted together. Butted Seam - YouTube. This shallow dip creates a hollow for the tape.

The shorter edges of a drywall panel as well as any cut edges do not have a factory bevel. The best way to identify the cause of your bulging drywall is with a methodical step-by-step approach. Practice with mud and tape make those seams go away.

Installing drywall with as few butt joints as possible makes invisible seams more attainable. To fix bugling drywall you can fix it in two different ways. The butted edge of the second panel is screwed through the drywall into the back-blocker.

Butt joints are challenging to finish because they require that you build a slight gradual mound to hide the joint. When drywall sheets with uncut edges are butted together a depression forms along the line where they join. It creates a concave depression that you can fill with a thin compound.

The raised edge of the RockSplicer helps recess the seam. To conceal the bump it will be necessary to feather the seam much wider than you would normally do so and it may require more than three coats of compound. Each of these issues could be the cause of your issue.

Where you have the ends of a piece of drywall falling between studs that normally geta cut back to a stud. It eliminates one of the last major problems with drywall finishing. If playback doesnt begin shortly try.

Drywall panels too close together. As the drywall goes up the butt ends are arranged to fall between the ceiling joists. Butt boards are a way of compensating for a lack of taping skills thus not entirely a bad idea.

Bulging drywall seams can also be caused by leaks and homes that have undergone considerable settling. Where two short non-tapered edges meet is called a butt joint. Butted ends of drywall are not tapered therefore when they are tapped a slight bump is created.

Attach the second panel. Staggering drywall seams prevent the matching up of joints from one row with that of another. When the adjacent drywall panel is screwed to the plywood strip a shallow dip is created where the drywall bends over the poster board.

When you have butt seams apply the compound in a thin layer and fan out the joint compound to help the area blend in with the wall. The lack of a factory bevel. Installing drywall shims to the joists can help ease the problem facing the butt joint.

The butted seam on the left attached to framing is finished over 30 inches wide and is still a bump. This can happen if the finished work is poor or there are two sheets of drywall that are butting too close together. Heres yet another possible cause.

The seam where these flat edges meet is called a butt joint. This will cause bulges or crowing along the seams.

How To Finish Drywall Butt Joints Do It Yourself Help Com

How To Finish Drywall Butt Joints Do It Yourself Help Com

Tips On Installing Drywall Butt Joints

Tips On Installing Drywall Butt Joints

/pov-hands-at-work-559442831-584821283df78c0230f89047.jpg) Drywall Joints Butt Vs Tapered

Drywall Joints Butt Vs Tapered

:max_bytes(150000):strip_icc()/taperedjoint-56a49bff5f9b58b7d0d7cd54.jpg) Drywall Joints Butt Vs Tapered

Drywall Joints Butt Vs Tapered

Eliminating Problems With Drywall Butted Seams This Is Drywall

Eliminating Problems With Drywall Butted Seams This Is Drywall

Eliminating Problems With Drywall Butted Seams This Is Drywall

Eliminating Problems With Drywall Butted Seams This Is Drywall

Eliminating Problems With Drywall Butted Seams This Is Drywall

Back Blocking Butted Drywall Seams Fine Homebuilding

Back Blocking Butted Drywall Seams Fine Homebuilding

Eliminating Problems With Drywall Butted Seams This Is Drywall

How To Avoid Drywall Callbacks Jlc Online

How To Avoid Drywall Callbacks Jlc Online

How Do You Like My Butt Joints Drywall Finishing Tips The Space Between

How Do You Like My Butt Joints Drywall Finishing Tips The Space Between

Comments

Post a Comment